PCBA Coating: Ensuring Effective Surface Protection for Electronic Components

Introduction

In the world of electronics, protecting electronic circuit boards and it Rigid-flex PCB manufacturer s components plays a vital role in ensuring their longevity and reliability. One popular method used for surface protection is PCBA coating. This article aims to provide an overview of PCBA coatings, including its manufacturing process, characteristics, advantages, usage methods, tips on selecting a manu Electronic circuit board coating facturer, and conclusion.

Manufacturing Process

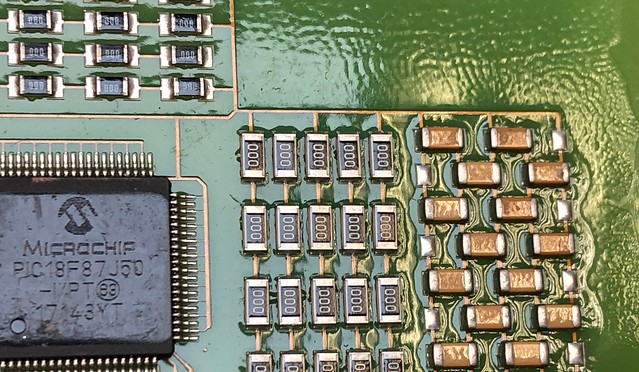

PCBA coating refers to the application of protective substances onto electronic circuit boards and its components. This coating can either be applied manually or through automated PCBA Coating processes such as spraying or dipping. Manufacturers carefully choose materials that adhere well to surfaces while providing exceptional insulation properties.

Characteristics

Electronic circuit board coa Surface protection for electronic components tings offer several important characteristics that make them suitable for various applications. These coatings are typically designed with high dielectric strength to prevent electrical shorts between traces on the board’s surface. They also possess excellent chemical resistance against environmental factors like moisture, dust particles or corrosive substances.

Advantages

There are numerous advantages associated with using PCBA coatings:

1) Enhanced Reliability: The primary purpose of these coatings is to protect electronic components from h

arsh environmental conditions that may cause premature failure.

PCBA Coating manufacturer 2) Increased Lifespan: By preventing contact with contaminants such as dirt or moisture, PCBAs enjoy extended lifespans.

3) Improved Performance: Coatings contribute towards reducing noise interference by minimizing signal degradation caused by electromagnetic radiation.

4) Cost-effective Solution: Opting for proper surface protection reduces maintenance costs significantly.

Usage Methods

The application method depends largely on the type of coating

being used. Spray coating involves evenly applying mist-like droplets over entire areas or selected sections using specialized equipment. Alternatively, dipping immerses PCBAs into chemical baths containing special coatinp\s,drying steps must be followed meticulously before further processing can occur.s For both methods,

Choosing a Manufacturer

Selecting an experienced PCBA Coating manufacturer i Component-level encapsulation s essential to achieve desired results. When choosing a manufacturer, consider the following factors:

1) Expertise: Look for manufacturers with extensive experience and knowledge in PCBA coating technologies.

2) Quality Control: Ensure that the manufacturer follows strict quality PCBA Coating control measures to guarantee consistent and reliable coatings.

3) Customization Capabilities: If you PCBA Coating r electronic components have specific requirements or unique dimensions, opt for manufacturers capable of providing tailored solutions.

Conclusion

PCBA coating offers an effective solution for surface protection on electronic circuit boards and its components. With characteristics like high dielectric strength and chemical resistance, it ensures enhanced reliability and increased lifespan. By reducing noise interference and being cost-effective, PC PCBA Coating manufacturer BA coatings are widely used in various industries. To ensure successful implementation, partner with a reputable manufacturer who possesses expertise in this field, ensuring optimal results.

In conclusion, employing efficient surface protection meth

ods such as PCBA coating is crucial to maintain the performance and longevity of valuable electronic components.