PCBA Coating: Enhancing the Performance and Durability of Printed Circuit Board Assembly

Introduction:

As technology continues to advance at a rapid pace, electronic devices are becoming increasingly compact and complex. The need for efficient printed circuit board assembly (PCBA) coatin PCBA coating g has never been more critical. This article will delve into the world of PCBA coating, exploring its manufacturing process, characteristics, advantages, application methods, tips for choosing a reliable manufacturer, and concluding with key takeaways.

Manufacturing Process:

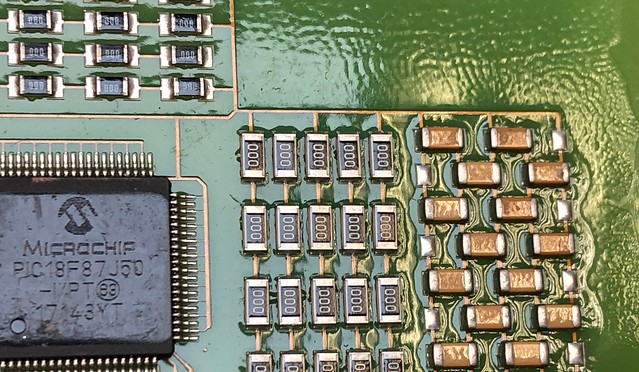

PCBA coating involves applying protective layers on electronic circuit boards to shield them from environmental PCBA Coating manufacturer factors such as moisture, dust particles, chemicals, temperature variations, and electrical interference. The process typically includes several steps:

1. Preparing the surface: Thoroughly cleaning the PCB to remove any impurities that could affect adhesion.

2. Application: Spraying or dispensing a specialized material known

as solder mask onto the PCB’s surface using automated machines or manual techniques.

3. Curing: Exposing the coated PCBs to high temperatures in an oven or through ultraviolet (UV) radiation to ensure proper curing and bonding.

Characteristics:

Printed circuit board assembly coatings offer numerous desirable characteristics that contribute to their widespread use in electronics manufacturing.

1. Insulation properties: The thin layer of coating acts as an insulating barrier between different components on the PCB while maintaining electrical conductivity where necessary.

2. Protection against harsh environments: PCBA coatings provide resistance against moisture absorption, dust penetration, chemical e Printed circuit board assembly coating xposure such as solvents/acids/bases/oils/greases/, extreme temperatures (-55°C up tp 125°C), salt spray corrosion etc., helping extend device lifespan even in challenging conditions.

3.Contaminate protection :Coatings resist contaminan Solder mask application ts like fingerprints which can lead reduction in impedance , deterioration due corrosive effect & Signal loss effect; alongwith protection againts Solder bridging)

4.Electrical insulation :Allowing it to be used where there is high density packing of components requiring proper input/output separation.

Advantages:

The advantages of using PCBA coatings are numerous and include:

1. Increased durability: Coatings significantly enhance the longevity and reliability of electronic assemblies by protecting them from external factors.

2.Improved performance:: By reducing the risk of short circuits, PCB coatings prevent system failure while ensuring optimal signal quali

ty.

3.Increased fault tolerance: Keeping moisture and contaminants away reduces the likelihood of malfunctions caused by unintended electrical pathways or component corrosion.

4.Ease of maintenance: Coatings simplify cleaning as they provide an easier-to-clean interface since dust particles or residues adhere less readily when a coating is applied.

Application Methods:

PCBA coatings can be applied using various techniques, each offering specific advantages depending on requirements:

1.Spraying/Dipping method : Spray coating/dip coating involves immersing PCBs into a speci PCBA Coating ally formulated solution followed by removing excess solvent via draining /air-knife blowing & then allowing board to dry naturally in oven/at RT /UV cure

2.Selective Application : Instead covering entire board , only specified areas needing coverage (Eg:Connector housing critical part without causing coverage over connector contact ) are covered/coate PCBA Coating d (Can use Mask/Stencil/Customized application methodologies)

How to Select a Reliable PCBA Manufacturer:

Choosing a reputable manufacturer for your PCBA coating needs is crucial for obtaining high-quality products efficiently. Consider the following factors during your selection proce PCBA Coating manufacturer ss:

1.Experience and expertise: Look for manufacturers with extensive experience in PCBA fabrication &Coating along with working knowledge in materials science; Thus able answer any queries regarding suitable material selections accordingly

2.Quality certifications: Ensure that the manufacturer has necessary approvals such as IPC-CC830B, RoHS, REACH etc.,indicative them adherenece specfied Technical standards/regulations fields Of Electronics field)

3.Manufacturing capabilities: Verify if the manufacturer has state-of-the-art facilities, advanced equipment, and skilled technicians to meet your specific coating requirements.

4.Customization options: A reliable manufacturer should be able Rigid-flex PCB manufacturer to offer tailored solutions that align with your unique needs while providing technical support throughout the process

Conclusion:

Printed circuit board assembly coatings play a pivotal role in protecting electronic devices from environmental factors, extending their performance life and ensuring optimal functionality. By selecting a reputable PC PCBA Coating BA coating manufacturer who understands your specific requirements, you can achieve enhanced device durability and reliability. Remember to consider factors such as experience, quality certifications, manufacturing capabilities, and customization options when choosing a manufacturer. Embrace the power of PCBA coating to unlock the true potential of your electronic assemblies!