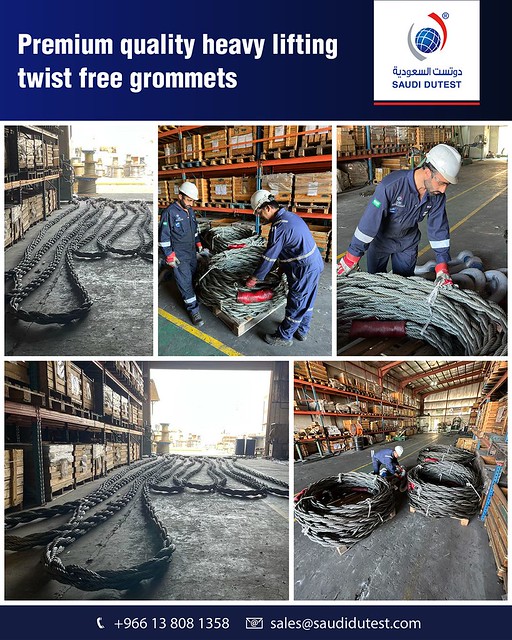

Lifting Slings: An Essential Tool in Lifting and Rig lifting slings ging

Introduction:

Lifting slings are an essential component of the lifting and rigging industry. They provide a secure and reliable method for hoisting heavy loads. This article will explore the manufacturing process, characteristics, advantages, proper usage, tips for selecting the right product, and conclude with key takeaway lifting and rigging supplies s.

Manufacturing Process:

Lifting slings can be made from various materials such as polyester, nylon, wire rope, or chain. The material chosen depends on factors like load weight capacity, desired flexibility or stiffness, resistance to abrasion and cutting hazards lifting slings . These materials undergo rigorous testing to ensure their strength and durability before being used in production.

Characteristics:

One of the main characteristics of lifting slings is their ability to evenly distribute weight across a wide surface area lifting slings . This feature reduces stress concentration points on cargo while minimizing damage risks during lifting operations. Lifting slings also possess excellent tensile strength which enables them to withstand heavy loads without compromising safety.

Advantages:

The use of lifting slings offers several advantages over alternative methods like tow ropes or tie-down straps. Firstly, t

hey provide better load stability due to their wider contact area with cargo surfaces. Secondly, using lifting slings eliminates the need Lifting straps for multiple attachment points by offering adjustable lengths that can accommodate various lift heights or angles seamlessly.

Proper Usage:

When using lifting slings it’s crucial to follow proper procedures outlined by manufacturers a

nd regulatory bodies.

1. Inspect your sling regularly for signs of wear/damage before each use.

2. Ensure proper positioning so that all parts bear equal weight distribution.

3.Safely store your sling when not in use.

4.Avoid sharp edges/load contact points that may cause damage.

How To Select The Right Product:

Selecting the appropriate lifting sling requires careful consideration of numerous factors:

1.Load Weight Capacity – Choose a sling rated above your heaviest expected load.

2.Environmental Conditions: Consider fact

ors like temperature extremes, chemical exposure, or UV radiation t Tie-down straps hat may affect the sling’s material properties over time.

3.Flexibility vs. Stiffness – Select a sling with appropriate flexibility to create secure connections without compromising stability.

Conclusion:

Lifting slings are indispensable tools in the lifting and rigging industry. They provide a safe and efficient method for lifting heavy loads while minimizing damage risks. By understanding their manufacturing process, characteristics, advantages, proper usage guidelin lifting slings es, and selecting the right product based on spe Tow ropes cific needs; users can ensure maximum safety and efficiency in their lifting operations.

In conclusion, investing in quality lifting slings is crucial for any business involved in heavy-duty lifting operations. With their impressive strength and ability to evenly distribute weight, they offer unparalleled reliability while ensuring the utmost safety of both workers and equipment. So remember to choose wisely and prioritize your crew’s well-being by opting for trusted manufacturers that guar lifting and rigging supplies antee premium-quality products.