High Frequency PCB: The Future of Electroni

cs

Introduction:

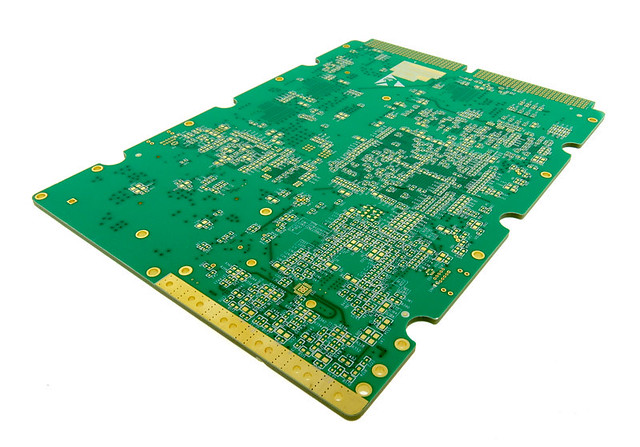

In the world of electronic devices, High Frequency PCBs have emerged as a game-changer. With their ability to meet the demands of high-speed and high-frequency applications, they have become an indispensable component High Frequency PCB in various industries. This article aims to explore the manufacturing methods, characteristics, advantages, usage tips, and guidelines for selecting these cutting-edge products.

Manufacturing Methods:

High Frequency PCBs are typically manufactured using specialized techniques such as FR-4 material combined with PTFE or Rogers substrates. These substrates provide excellent electrical properties necessa High-speed PCB ry for high-frequency signal transmission and minimize signal losses by reducing dielectric constant variations.

Characteristics:

High-speed PCBs offer remarkable electrical performance due to low insertion loss and minimal impedance variation across frequencies up to GHz range. Their multilayer structure e

nables them to provide exceptional electromagnetic shielding and reduces crosstalk between neighboring components significantly. Furthermore, Aluminum PCB these boards possess superior mechanical stability under thermal stress.

Advantages:

One significant advantage is that High Density Interconnect (HDI) technology can be implemented effectively in designing High Frequency PCBs. HDI-PCBs enable small Aluminum PCB er pad sizes and finer pitch traces which contribute to increased circuit density while minimizing parasitic capacitance and inductance effects.

Another advantage lies in Radio Frequency (RF) circuitry applications where RF PCB expertise becomes vital for ensuring precise impedance control on all copper features like tracks, pads, gaps & vias at any given frequency within the target range.

Microwave communication systems require special types of M High Frequency PCB icrowave PCBs tailored explicitly for frequencies above 1GHz. These specialized boards offer stable performance under extreme temperature conditions needed by critical microwave devices employed in satellite communications or wireless medical equipment.

Usage RF PCB (Radio Frequency PCB) Tips:

When using High-Frequency PCBs during assembly processes involving SMT (Surface Mount Technology), it’s crucial to consider optimized pad geometry & thickness along with proper solder p High Frequency PCB aste deposition techniques specifically designed for high-frequency signals.

How to Select High Frequency PCBs:

To select the High Frequency PCB most suitable High Frequency PCB, consider factors such as dielectric constant (Dk), dissipation factor (Df), signal losses, isolation properties, and thermal performance. Additionally, analyzing the manufacturer’s reputation and certifications for quality control can ensure reliability.

Conclusion:

High Frequency PCBs offer unparalleled advantages in terms of e HDI-PCB (High Density Interconnect-Printed Circuit Board) lectrical stability and performance for high-speed applications. Their ability to handle complex circuitry while maintaining low signal loss makes them an ideal choice for industries requiring cutting-edge electronic solutions. Manufacturers specializing in these products coupled with

proper selection criteria will undoubtedly pave the way towards a more technologically advanced future.